Integrated crop production: A future shaped by smart technologies

Integrated crop production has long been considered a proven, environmentally friendly farming system, though in recent years, it has somewhat faded from focus. Today, however, innovative new solutions are once again bringing this approach to the forefront of practical farming. Modern sensor-supported technologies and digital tools are making it possible to maintain the use of crop protection as a key element of integrated crop production — even as more active substances are withdrawn from the market.

For nearly four decades, integrated crop production has stood for a holistic and sustainable approach to arable farming. It encompasses a wide range of cultivation practices designed to maintain plant health and support crop development, ultimately leading to productive and resilient stands. Within this framework, integrated crop protection plays a critical role, prioritizing preventative and non-chemical measures. Chemical control is considered only after other strategies have failed to deliver the desired effect.

Following the damage threshold principle, weeds and pests should be managed as effectively as possible i.e. ideally through non-chemical methods. In practice, however, integrated crop production and protection have not always been implemented as comprehensively as would be ideal for today’s conditions. This is largely because modern crop protection products, fertilizer technologies, and breeding advances have often masked underlying agronomic issues. These are issues that stem from tighter crop rotations, early sowing dates, and increased nitrogen fertilization.

In recent years, the decreasing availability of active substances and the growing problem of resistance — especially in the control of weeds and grasses have compounded these challenges. Climate change, with its weather extremes, prolonged droughts, and the emergence of new pests, has further intensified the situation. As a result, many farmers are once again turning to integrated crop production.

Mechanical weed control on the rise

Mechanical weed control is becoming increasingly relevant, even in conventional farming, as more of the conventional chemical herbicides cannot be employed due to regulatory restrictions while few new active ingredients are being introduced. Combined with rising resistance levels, this poses major challenges for weed and grass control in arable farming.

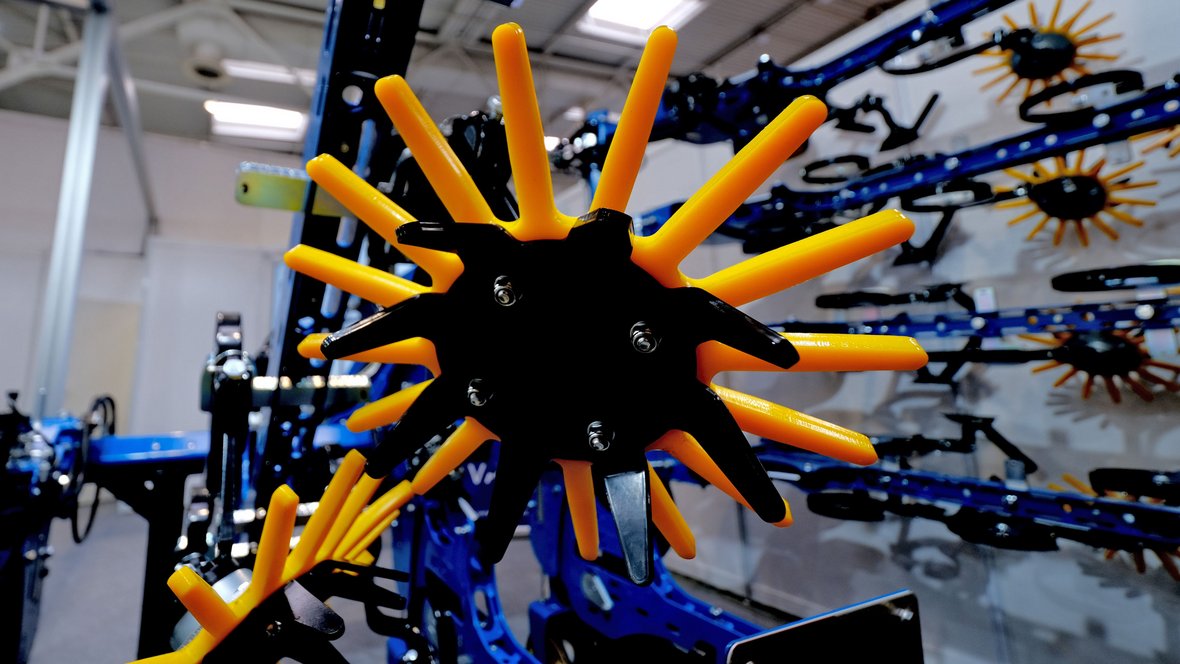

Integrated crop production increasingly relies on the combination of mechanical and chemical methods, supported by modern sensors and precision control systems. Mechanical tools can now be steered by cameras, both between and within rows, allowing for high-speed operation and significant reductions in chemical inputs. New developments also include AI-driven systems to optimize the control of hoeing equipment.

Despite its advantages, mechanical weed control is not without challenges. Wet years, the risk of soil compaction and erosion, as well as gaps in practical know-how, can limit its effectiveness. Additionally, mechanical methods often fall short in controlling certain persistent weed species.

Precision in chemical crop protection

Even as more active ingredients are phased out and resistance increases, chemical crop protection will continue to play an important role in integrated crop systems. This is supported by innovative, high-precision technologies that help reduce pesticide use.

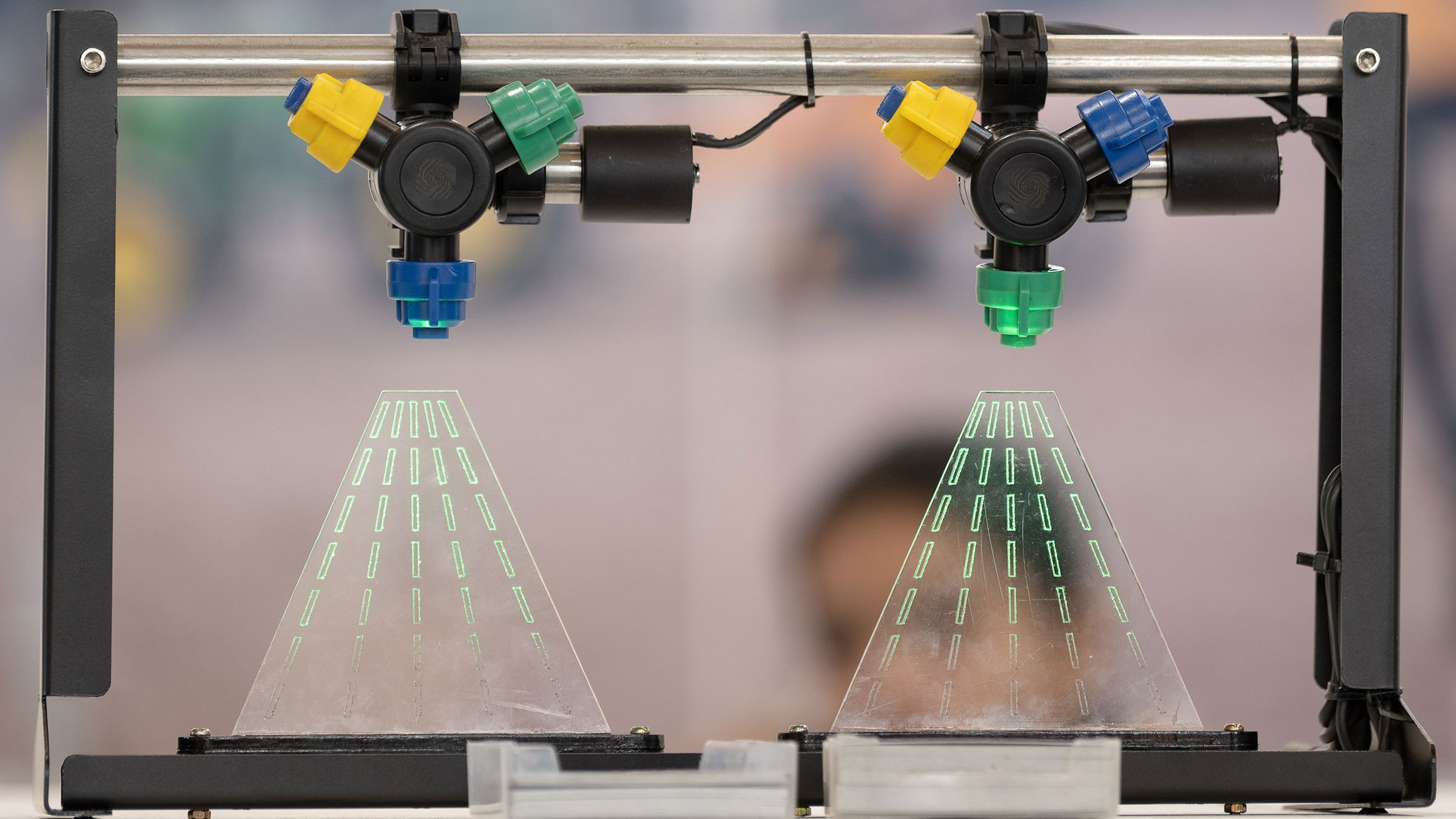

Site-specific application systems allow for treatments to be tailored to the yield potential of sub-sections within large fields. Spot-spraying technology enables pinpoint application, further improving accuracy and reducing input volumes. Pulse-width modulation allows for rapid electronic control of nozzle output during turns, preventing over-application on inner curves. GPS-guided section control prevents overlap in headlands and wedges.

Digital pest monitoring solutions — for example, in oilseed rape — support in-field decision-making. Field robots are currently being tested in research projects; while high costs and low area coverage still limit their use, they are seen as a realistic option for the future. Drones are unlikely to be used for large-scale spraying in arable crops, but they are proving useful for targeted applications, such as deploying beneficial insects to combat corn borers, a method that has already shown success.

A 2024 study by the digital association Bitkom and the DLG (German Agricultural Society) shows just how highly German farmers value digital tools. According to the study, 91% of respondents believe digital technologies help reduce the use of pesticides, fertilizers, and other resources. Already, 30% of farms are using site-specific crop protection applications (up from 23% in 2022). The greatest potential for AI in agriculture is seen in prediction models and crop protection.

Precision in mineral fertilization

Fertilization — especially nitrogen management — is another integral part of integrated crop production. One of its key goals is to minimize nutrient runoff into water bodies. Additional objectives include reducing mineral fertilizer use and improving application efficiency.

Agricultural machinery manufacturers are addressing these needs with sensor-assisted rate control, enhanced border spreading systems, automatic section control, variable rate adjustment, and systems that optimize spreading patterns on curved tracks. Pneumatic fertilizer spreaders ensure precise distribution along field edges.