Innovation Award EuroTier 2024

EuroTier, the world’s leading trade fair for animal farming and livestock management, has established itself as the most prominent platform for the introduction of innovations. This innovation leadership is underlined by the EuroTier Innovation Award, which is handed to the winners at the show every two years.

An independent expert jury appointed by the DLG (German Agricultural Society) using stringent criteria has selected the winners of the Innovation Award EuroTier. With four gold and 21 silver awards, the Innovation Award EuroTier 2024 in gold or silver has been awarded to a total of 25 product innovations from 214 qualified submissions.

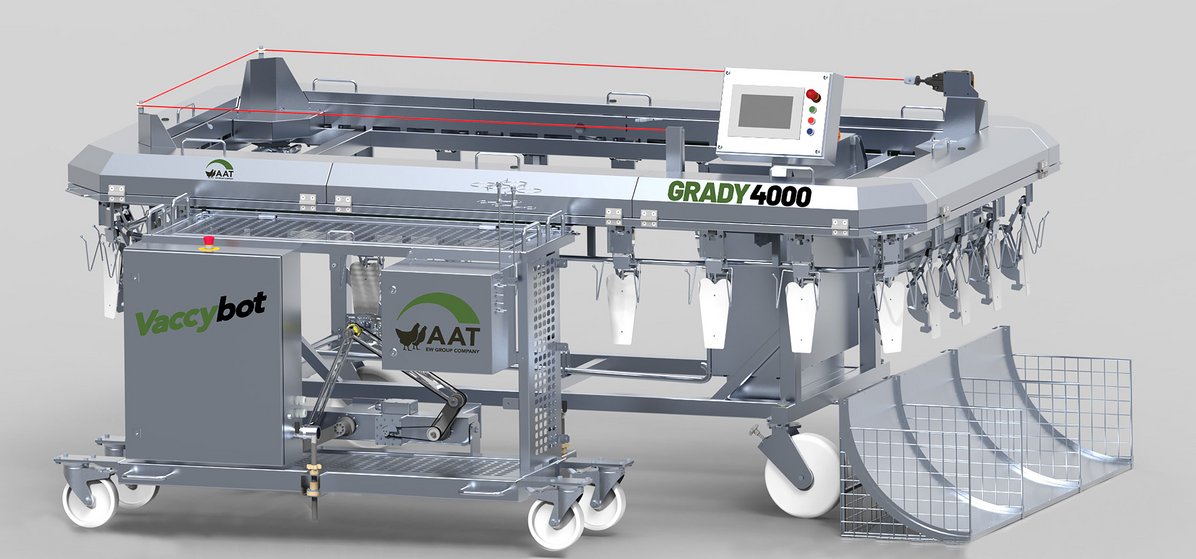

Vaccybot

Hall 17, Stand B20

The Vaccybot from Agri Advanced Technologies is the first fully automated vaccination robot for poultry farming and has the potential to replace the error-prone manual needle vaccination that has been common until now. For the animals, the process means less stress and at the same time higher vaccination quality and improved animal health, and for the livestock farmer it is a real labour-saving solution.

Young hens are needle vaccinated with several vaccines during rearing before being transferred to the laying farm, i.e. vaccination is carried out by intramuscular injection using hypodermic needles. Until now, vaccinations have been carried out manually, which can cause stress and pain for the animals and harbours a certain risk of pathogen transmission or broken needles in the animal and later in the meat.

Agri Advanced Technologies has now developed Vaccybot, the first fully automated process for breast vaccination in poultry. It is a new development that has the potential to revolutionise poultry vaccination in terms of accuracy and vaccination success. The system enables the simultaneous injection of up to six different vaccines with unrivalled precision and speed. The innovative technology, which uses a 3D stereoscopic NIR camera and a real image colour camera in conjunction with intelligent algorithms, measures the animals manually suspended in an existing sorting device and passing by in the sub-millimetre range and calculates the exact target position for vaccination within milliseconds. The dynamic control of a 2D delta robot arm with six axes enables the vaccines to be applied with pinpoint accuracy of one square centimetre. This not only leads to a considerable improvement in vaccination quality, but also significantly reduces stress for the animals. In addition, the system improves operational and labour management by reducing the number of work steps and ensuring the consistent quality of vaccinations, which can help to improve animal health.

Overall, automated vaccination with the Vaccybot fulfils the criteria for the gold medal in an outstanding way and represents a significant advance in modern poultry farming.

Cow-Welfare Flex Air Stall

Hall 12, Stand B49

The Flex Air barn system from Cow-Welfare is the first to realise a direct supply of fresh air into the lying area of individually lying cows, thus supporting effective cooling and helping to prevent heat stress.

Animal Welfare Award 2024

With rising ambient temperatures from around 24 °C and humidity levels of around 70 %, high-yielding dairy cattle increasingly reach the limits of their thermoregulation and suffer from heat stress. To avoid this, the animals change their behaviour significantly and try to bring their body temperature back into balance by releasing more heat.

The most effective way to support the animals with regard to the climate in the barn is to cool them through air movement and fresh air supply. In addition to free ventilation through the removal of external walls, fans or ventilation hoses are usually installed to bring fresh outside air into the barn area.

The Flex Air barn system from Cow-Welfare now makes it possible for the first time to supply fresh air directly into the cows' lying area. Fresh outside air is sucked into the barn via a hose ventilation system and pressurised into the cubicles. The fresh air is then forced directly into the cubicle area at an angle of 45° from five holes in the upper cubicle frame. In this way, the cubicle becomes the most comfortable and best ventilated place in the barn where the cows like to spend time.

The Flex Air cubicle system promises effective cooling and fresh air supply for the individual cow lying down, thus helping to prevent heat stress.

CalfGPT

Hall 13, Stand D35

CalfGPT from Förster-Technik enables voice-controlled, AI-supported data management in calf care for the first time, making calf management much easier.

The daily work and care of calves on a farm requires a lot of time and attention. This is particularly important as calves are the future dairy cows and this phase of their lives is crucial for later milk production. Sensors and automatic feeders record a lot of data and information in the calf area, which helps the farmer to keep an eye on the calves' behaviour and health. However, the retrieval and entry of this data is often laborious at the automatic feeders, via handheld terminals or far away from the calves in the barn office on the computer.

With CalfGPT, Förster-Technik offers an innovative management tool based on the leading AI system from OpenAI. It enables the farmer to make freely formulated enquiries about the general situation or about individual calves via a voice connection in the farm's own WLAN and to receive targeted information about the calves and alarms on the mobile phone or tablet as a direct response. Pre-formulated commands are not necessary; new information on individual calves can also be sent directly to CalfGPT verbally for further documentation.

Using the application via in-ear headphones simplifies operation considerably. Entering findings in particular is made easier, as the user has both hands free to work on the animal even when "entering". Users can also obtain a targeted digital overview of their calf groups during other activities in the barn, such as bedding or feeding, which saves time and can be realised "hands-free".

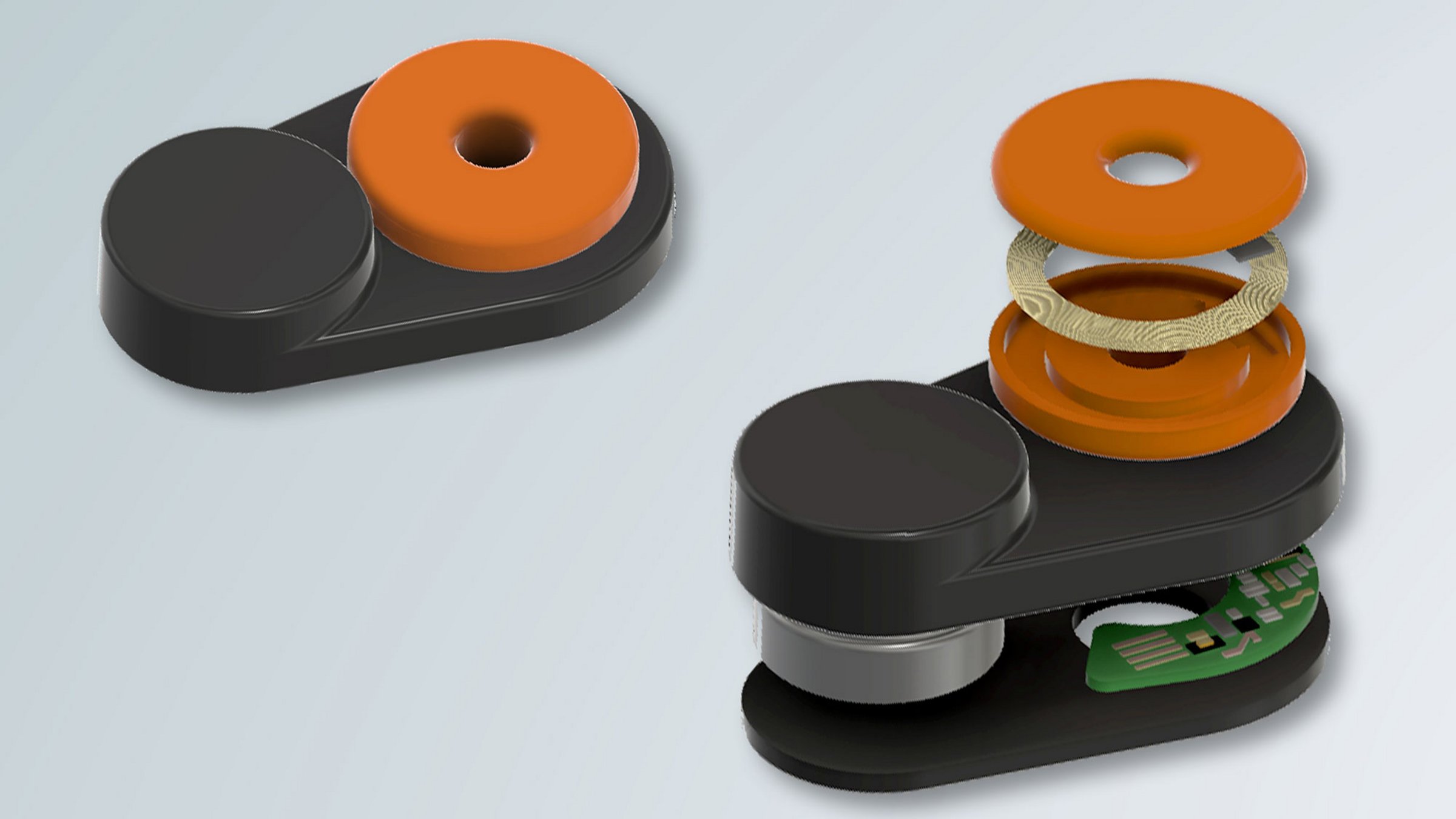

Cold plasma mite trap EX

Hall 15, Stand D26

The cold plasma mite trap EX from MIK International is the first technical system for residue-free control of the red mite, which has the potential to replace the chemical control methods used to date.

In co-operation with:

- Friedrich-Loeffler-Institut, Federal Research Institute for Animal Welfare and Animal Husbandry,

- HAWK University of Applied Sciences and Arts, Faculty of Engineering and Health, Laser and Plasma Technology

The red mite is found in poultry houses worldwide, especially in laying hens. The ectoparasites live and reproduce in the direct environment of the animals and come onto the animals during the dark phase to suck blood. If the mites multiply en masse, animal health and profitability are severely impaired. The red mite is currently controlled using acaricides, silicates or antiparasitics. A technical system for controlling the red mite has not existed until now.

The new technology of the cold plasma mite trap EX from MIK International uses a mite trap to control the mites. In this trap, the mites are exposed to a cold atmospheric pressure plasma generated by dielectric barrier discharge in a discharge chamber. This is located between an electrically positively chargeable electrode covered by a dielectric and an earthed electrode. The effect on various stages of development, i.e. the mite itself and mite eggs, was demonstrated in a test. The mite traps are placed underneath the perches and are equipped with an automatic cleaning system that pushes the dead mites out of the trap.

The cold plasma mite trap EX could reduce the use of acaricides, silicates or antiparasitics in the future and achieve a significant improvement in animal health and profitability. It therefore fulfils the criteria for the award of the Gold Medal in an outstanding way.

The winners of the Innovation Award in silver are

Hall 17, Stand B20

The disinfection of hatching eggs is indispensable in hygiene management and, in addition to improving hatching success, also serves to prevent animal diseases. Previous methods, some of which used substances that are harmful to health, are banned or at least viewed critically for ecological and health and safety reasons.

The eggytizer from Agri Advanced Technologies relies on the use of electron beam sterilisation technology (eBeam) to disinfect hatching eggs. This form of sterilisation with accelerated electrons enables a greater penetration depth into the eggshell than conventional treatments with UV or ozone. The process enables a higher level of disinfection than conventional methods. Overall, the improved disinfection performance is expected to lead to an improvement in animal health and an economic advantage, while at the same time eliminating the need for chemical disinfectants. In addition, better hatching results have been achieved in initial trials.

Overall, the eggytizer therefore makes a valuable contribution to modern poultry farming.

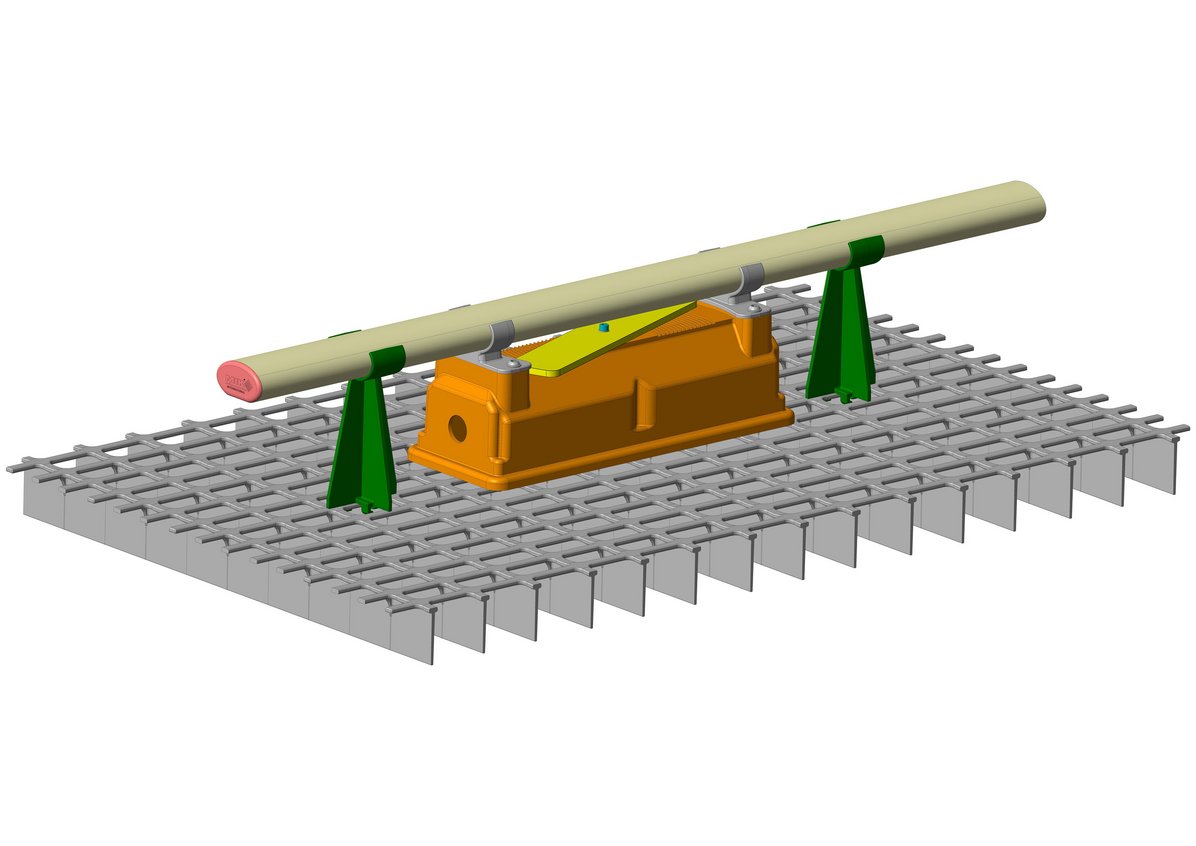

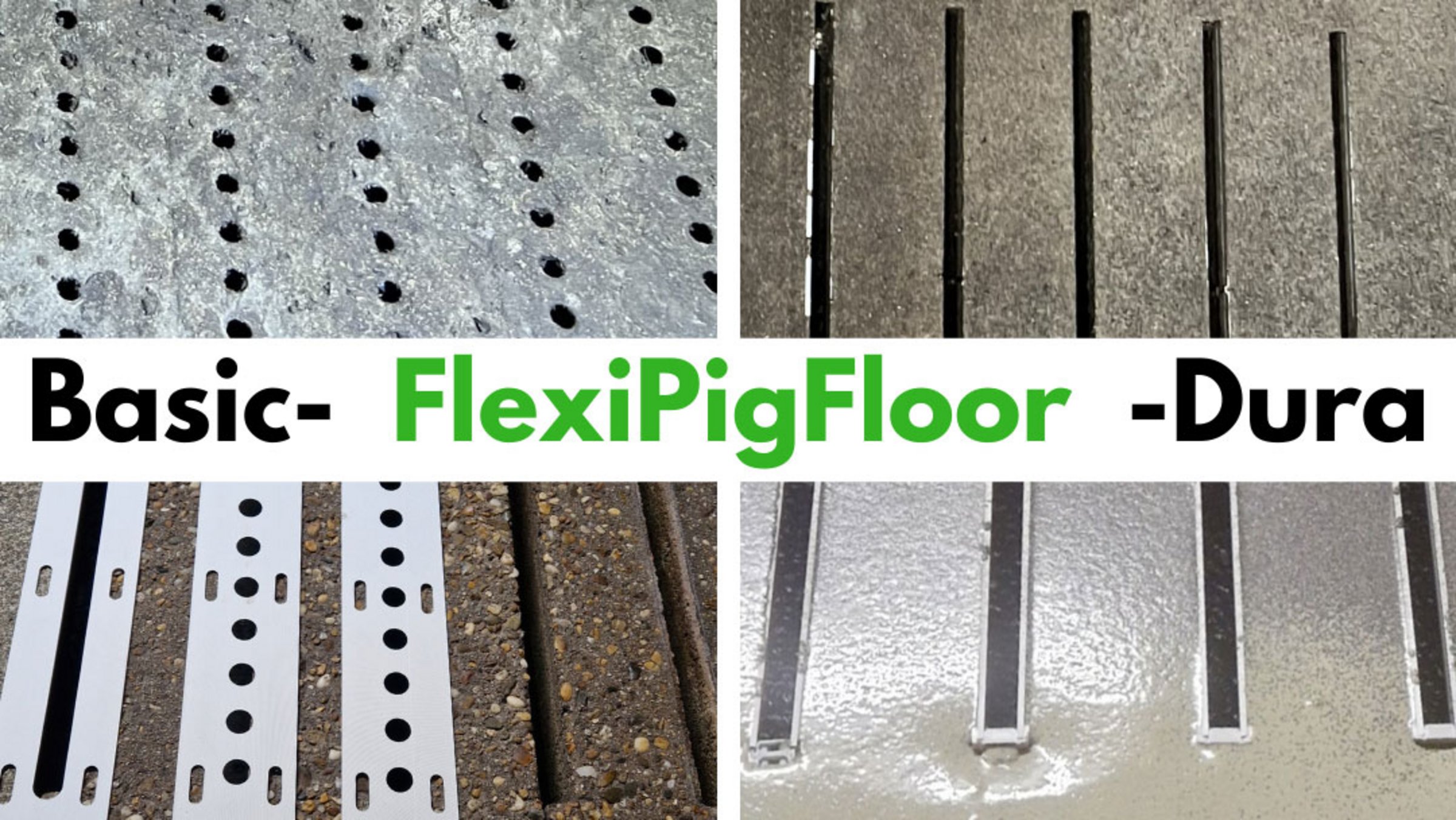

Hall 15, Stand E19

Livestock farming, and pig farming in particular, is constantly facing changes, for example due to new legal requirements, marketing requirements or adjustments to the housing facilities to improve animal welfare and farm development. Maintaining functional safety and legal compliance through to the renovation and repair of housing facilities is also a constant challenge. The concrete floor with perforation also plays a central role here. Adjusting the slot widths, reducing the degree of perforation or even simply refurbishing washed-out concrete floor elements are always a challenge.

The FlexiPigFloor system from ASBO enables simple, durable, fast and cost-effective repair and customised adaptation of existing concrete slatted floors to changed specifications for slot width and slot proportion as well as surface finish.

FlexiPigFloor consists of aluminium profiles that can be flexibly manufactured as required and a cement-based coating. The coated profiles can be used to repair existing concrete columns, adapt slot widths to changing legal requirements or convert existing concrete columns into a surface with a low degree of perforation.

FlexiPigFloor therefore offers an effective and efficient solution for renewing and remodelling concrete slatted floors. This means that existing floor systems can be adapted to new requirements without having to be dismantled.

Hall 16, Stand C03

The temperature stability of piglets is one of the most important factors influencing the survival rate of suckling piglets. Especially in farrowing pens designed for free farrowing, the challenge is to guide newborn piglets into the warmed piglet nest as quickly as possible.

With its ATX Thermonest ECO, ATX has significantly improved this heat conduction function. The patent-protected curtain lock can be folded down very easily with one hand and therefore effectively and quickly. The curtain is folded upwards when the lid is lowered, which makes operation much easier. The multifunctional board for conducting heat and closing off the nest is also a remarkable innovation. The board can be repurposed quickly, safely and technically sophisticated in just a few simple steps. Only 7 to 10 seconds are required per pen to set up the heat conduction function before farrowing, making the product an interesting option for large farms too.

The ATX heat conduction function for suckling piglet nests thus represents a significant further development of the piglet nest, which improves both the animal welfare of the piglets and the handling by the livestock farmer in a special way.

Hall 24, Stand A23

The state of the art of manually operated devices for cleaning technology in agricultural livestock management systems has not evolved for years. The devices essentially consist of a high-pressure gun that is connected to a lance on one side and a high-pressure hose on the other.

By developing so-called exoskeletons, AUFRATECH now offers the user a significant relief when cleaning with a high-pressure cleaner. The EXON Dual and EXON Mini have been developed to significantly reduce the strain on the body during high-pressure cleaning tasks.

A lightweight, adjustable and comfortable tubular chassis and corresponding straps provide significant advantages when distributing the weight of the lance over the shoulder, as the reaction forces of the cleaning lance are distributed over the torso. It is also possible to attach the feed hose in the waist area. An ambidextrous command module, which is permanently positioned in front of the user, also results in a low trigger force.

A comfortable and perfectly balanced posture significantly reduces the drastic strain on the upper limbs, especially the shoulders. At the same time, there is less vibration and work productivity is significantly improved.

Hall 12, Stand F26

Previously, the straw bands or baler twine had to be manually removed from a straw bale after opening before it was fed into a straw distribution system. This meant that only one new bale could be fed into the bedding system at a time.

The BETEBE Strohexpress makes it possible for the first time to automatically remove the straw bands from the straw bales, thus minimising the susceptibility to errors in bedding systems for cubicle stalls, deep litter stalls or deep litter stalls. The automatic baler twine removal enables up to twelve bales of straw to be stored in a space-saving, vertical bale magazine. In conjunction with the bedding system, the system can provide fully automatic bedding and also minimise dust formation in the barn. The space-saving system can be installed in new barns as well as retrofitted.

The BETEBE Straw Express saves labour time thanks to the automatic baler twine removal and ensures more flexible working hours and improved work quality thanks to the bale magazine.

Hall 17, Stand D20

In co-operation with BioCV

While pedometers or sensor collars for recording health and fertility data are already common in the cattle sector, the functions of technically similar systems in the pig sector have so far been limited to locating sows in large groups, early detection of respiratory diseases via the background noise in the barn or initial attempts to minimise crush losses during farrowing with the help of camera or sound technology.

With the BioTag+ sensor ear tag from Big Dutchman and BioCV, movement and temperature data from pigs can be recorded for the first time in pig farming. With the help of algorithms, it is also possible to record individual parameters such as heat or imminent farrowing. Data is communicated via Bluetooth and analysed via a cloud with the help of AI. Even in the farrowing area, the BioTag+ system makes it possible to keep sows in groups until shortly before birth. This tends to lead to greater animal welfare, less stress and easier births.

The BioTag+ sensor ear tag from Big Dutchman and BioCV therefore represents a decisive further development in the sensor-based recording of animal condition data.

Hall 17, Stand D20

Young hens are vaccinated with several vaccines by needle during rearing before being transferred to the laying farm. This vaccination process, which is usually carried out manually using intramuscular injections with injection needles, exposes the animals to great stress. There is also a certain risk of pathogen transmission or broken needles in the animal and later in the meat, which can cause pain for the animal.

The MultiVacc vaccination machine from Big Dutchman represents a significant development in the field of poultry vaccination and offers significant improvements in function and process. MultiVacc is the first semi-automatic vaccination machine that can simultaneously administer four breast and one wing vaccination in an animal-friendly way by manually catching the birds and holding them in a specific position against the machine.

The economic significance of MultiVacc for the practice is considerable, as its efficiency and ergonomic design significantly increase labour efficiency and reduce the effort required for manual vaccinations. This not only leads to an improvement in the quality of work, but also to increased functional safety, as the risk of errors during vaccination administration is minimised and animal health can therefore be improved. The high hygiene standards that MultiVacc fulfils and the animal-friendly application, which reduces stress for the animals during the vaccination process, are particularly noteworthy.

Overall, MultiVacc makes a valuable contribution to vaccination safety in modern poultry farming.

Hall 17, Stand D20

In co-operation with Envirologic AB

Washing aviary houses in laying hen farming poses a challenge due to the complex and angled systems on various levels. With previous manual cleaning methods, some areas are difficult to reach, resulting in high labour costs and not always satisfactory cleaning results.

The Sharky430 from Big Dutchman International is an advanced washing robot for cleaning rearing and laying hen houses with aviary systems. The washing robot has been extended with a very flexible washing arm, which makes it possible to reach all areas in an aviary. The significant improvement of the washing robot arm with more degrees of freedom leads to a better cleaning result, as even hard-to-reach areas can be reached by the washing arm. As the first highly automated and flexibly programmable washing robot that has been specially developed for rearing and laying aviaries, it fulfils the practical requirements in an impressive way. The economic benefits of the Sharky430 are considerable, as its efficiency and flexibility significantly increase work performance and improve the quality of work at the same time. In addition, water can be saved and resources conserved. Thanks to the washing programmes supplied for Big Dutchman aviaries and the option to customise these programmes, the Sharky430 offers a high degree of flexibility and user-friendliness.

All in all, the Sharky430 washing robot makes a valuable contribution to modern poultry farming.

Hall 11, Stand F55

Young animals represent the future of every herd. Monitoring their health from birth therefore plays a crucial role for every dairy farm. Up to now, monitoring has mostly been carried out visually and the perception of illnesses is heavily dependent on the experience of the employees. Sensor monitoring has so far been very difficult to implement because the calves' organism changes considerably in the course of their young lives and the monitoring system has to take these growth-related changes into account or adapt to them.

The CowManager ear sensor is the first health monitoring system for calves. The algorithm utilises machine learning methods and thus enables the presentation of constantly improving predictions on the health status of the individual calf. The alarms are adapted to the age of the animals. As a result, diseases are recognised as early as possible, treatments are documented and health is continuously monitored from calf to cow.

In this way, CowManager-Youngstock can reduce the use of antibiotics and further optimise animal health - a significant improvement in calf management.

Hall 11, Stand D59

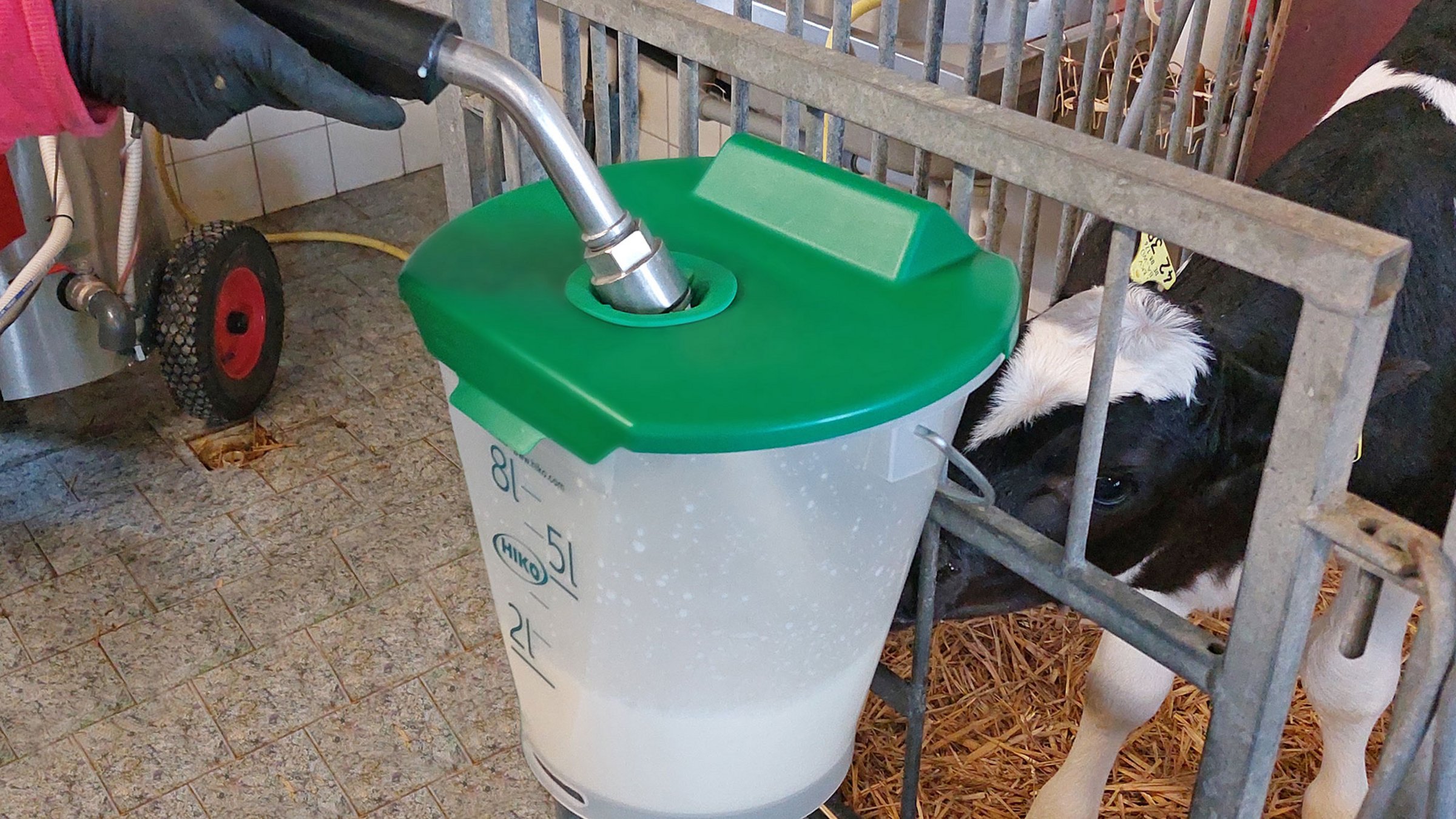

Calf rearing is still the most sensitive area in dairy farming. Feeding hygiene in particular is a high-priority issue. In fact, it is still very common to see open drinking buckets on calf igloos, because removing and refitting lids, especially when feeding with a milk taxi, takes a considerable amount of time, which many people shy away from. However, open drinking buckets greatly facilitate the entry of dirt and, above all, flies in summer.

With the Easyfill drinking bucket lid, Hiko offers a simple and above all practical solution to this problem. The lid has a self-closing opening through which the filler neck of the milk shuttle can be inserted at any time and the bucket filled. As the handling hardly differs from filling without a lid, a high level of acceptance among staff can be expected.

The Easyfill drinking bucket lid keeps the drinking buckets tightly closed, which largely prevents the entry of foreign matter such as dirt or flies.

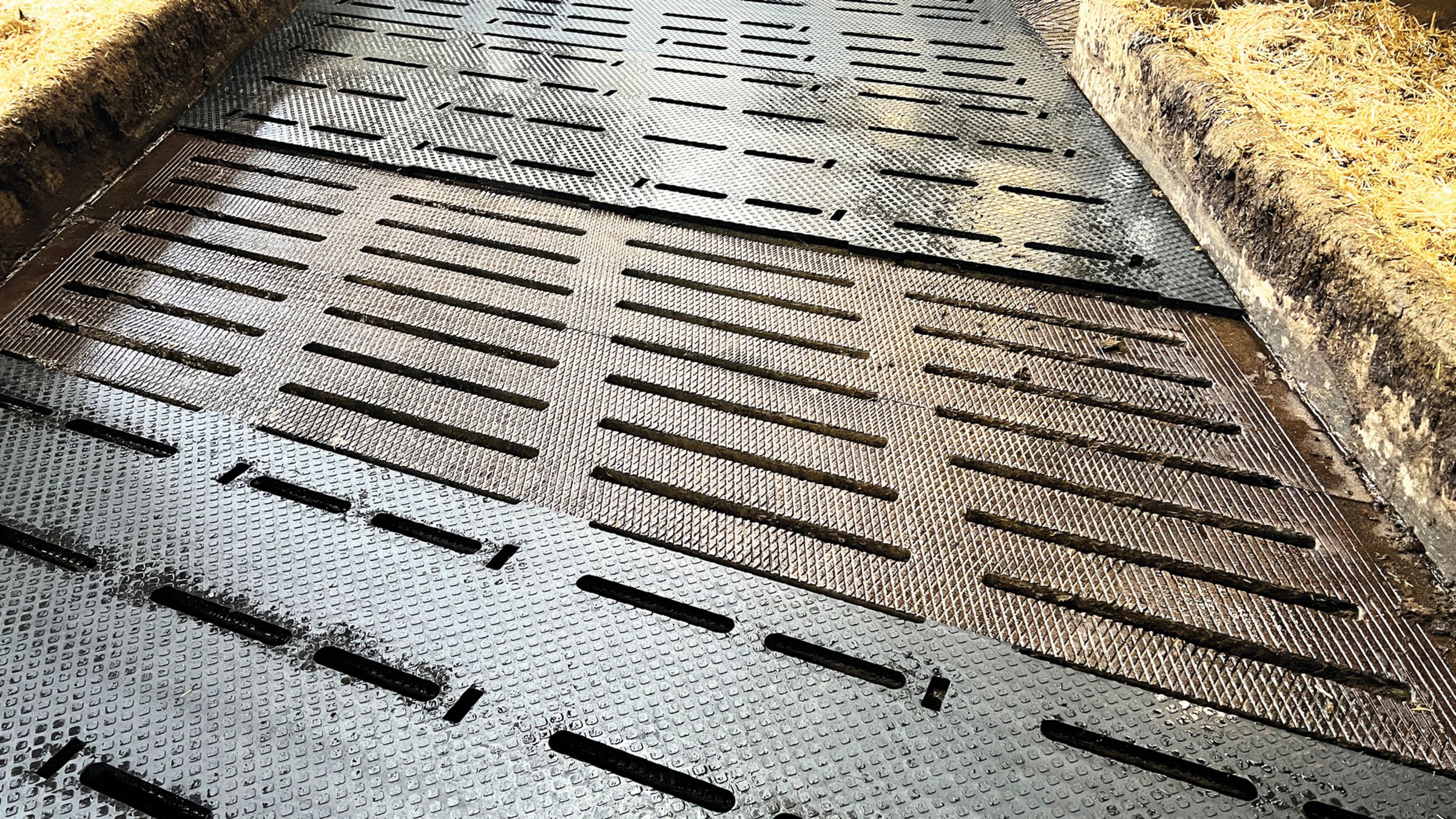

Hall 12, Stand E57

National and international regulations demand an increasing reduction of air pollutants - including those from livestock management. Ammonia plays a particularly important role here, which is produced in the cattle sector especially when faeces and urine are not separated immediately, the excrement remains mainly on walking surfaces and does not dry off promptly.

To solve this problem, Gummiwerk Kraiburg has developed the espaFLEX mat for new and existing slatted floor surfaces. The espaFLEX mat stands out from existing products on the market thanks to its special corrugated profile with a 3 per cent gradient structure across the running direction.

The 3 per cent slope allows urine to flow quickly through the slots, leaving a fast-drying walking surface. The improved dryness of the treads ensures drier hooves with corresponding positive effects on hoof health. Due to the special design, cleaning robots continue to achieve good cleaning results thanks to the gentle "wave".

The rapid drainage of urine and, in conjunction with manure-collecting robots, lower ammonia emissions can be expected in addition to the aspects for greater animal welfare and better claw health.

Hall 11, Stand B10

Particularly in the first few weeks of life, it is crucial for dairy farms to be able to recognise and treat calf diseases as early as possible. Until now, sensor-based monitoring like that for adult animals has been technically difficult to realise.

The SenseHub Dairy Youngstock ear tag sensor enables automated round-the-clock behaviour monitoring of calves and young cattle in the first twelve months of life for the first time. Behavioural parameters such as activity, suckling, eating and rumination are recorded via the electronic ear tag and can be linked to the herd management system. This allows potential health problems to be recognised at an early stage and recommendations for action to be derived. It is also possible to share the data with the herd veterinarian or counsellors.

The SenseHub Dairy Youngstock ear tag sensor can therefore be used to improve animal welfare and reduce the use of antibiotics in calf husbandry.

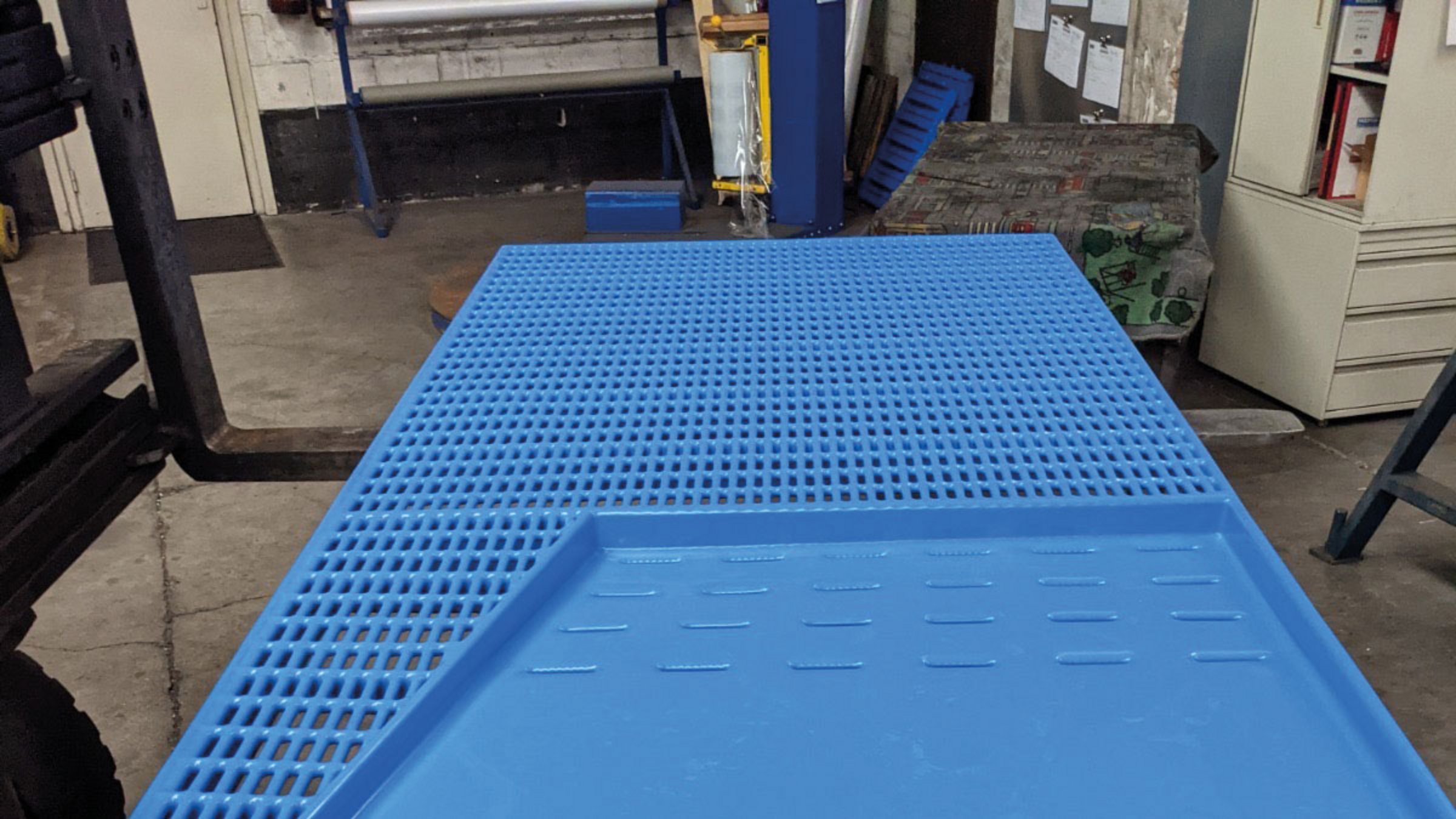

Hall 15, Stand B03

As an integral part of the farrowing pen, the piglet nest should help to equalise the differences in the heat requirements of sows and piglets in the first few days of life and reduce suckling piglet losses due to crushing. The farrowing pen must also fulfil particularly high husbandry and hygiene standards.

The lowered piglet nest from Nooyen Manufacturing offers several advantages here. The slightly lowered and inclined nest simulates a hollow. This means that the piglet nest is better accepted and the risk of crushing losses is reduced. Bedding or bedding powder can be placed in the hollow without causing excessive losses. The slightly perforated surface drains off liquids and the nest remains dry and hygienically clean. The heating system built into the piglet nest can be operated with hot water or electricity and provides even heat from below. The piglet nest is compatible with every farrowing pen and can be easily integrated into existing systems.

The Lowered Heated Piglet Nest from Nooyen Manufacturing therefore represents a decisive improvement in the design of farrowing pens.

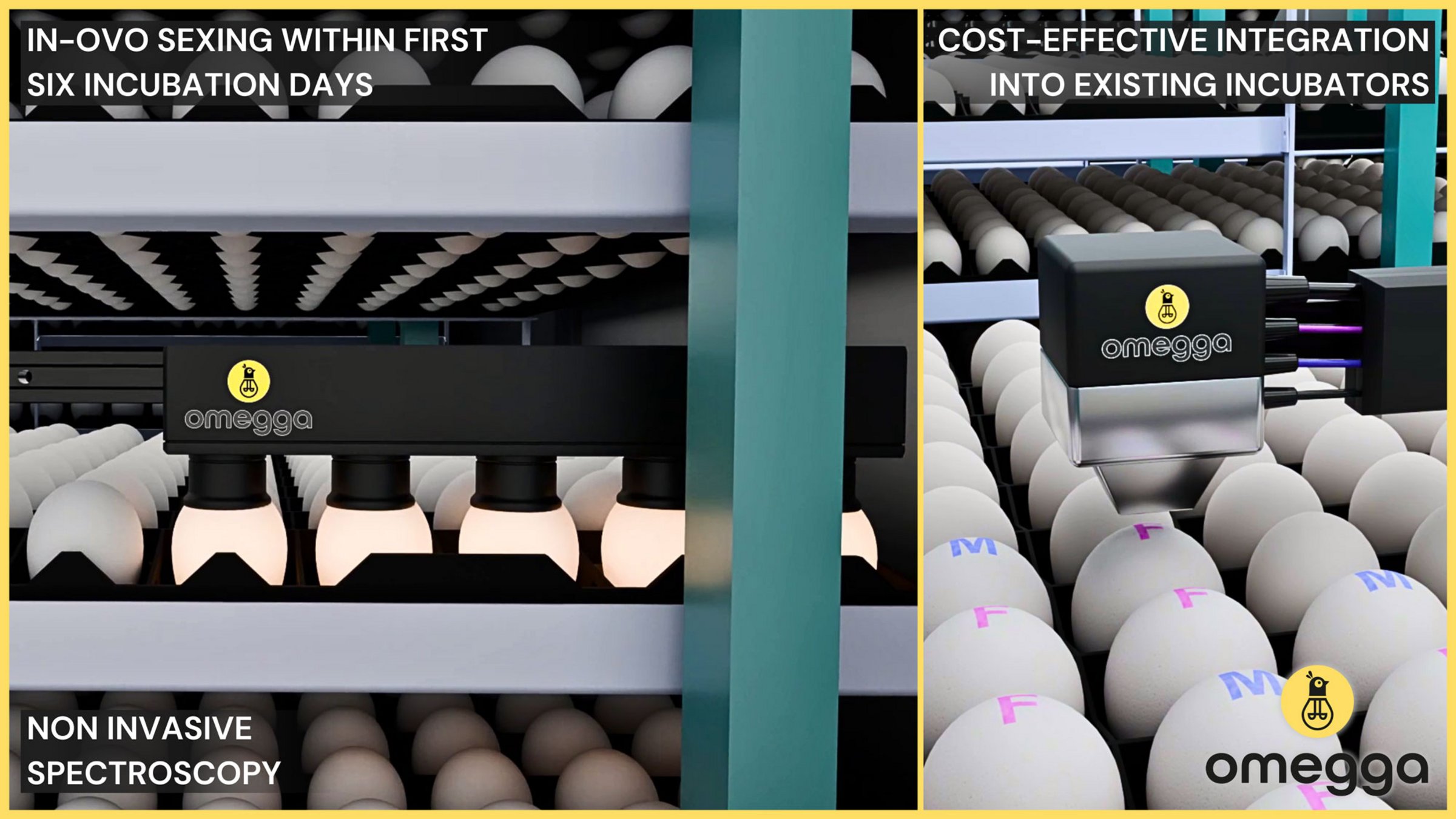

Hall 17, Stand H18

Due to intensive breeding optimisation for laying performance, the rearing of male chicks from laying breeds is not feasible. Since 2022, the routine killing of male chicks on the first day of life has been banned, making it necessary to reliably determine their sex while still in the egg.

By using non-invasive and cost-efficient, AI-supported spectroscopy, Omegga has significantly improved the technology for sexing laying hen chicks in the egg ("in ovo") with OmeggaOne. The newly developed system recognises the sex up to the seventh day of incubation without the need for any chemical or physical intervention in the egg and therefore without affecting the embryonic development of the chicks.

This avoids the unnecessary killing of male chicks from an ethical, animal welfare and sustainability perspective and increases efficiency by saving space and resources in the hatchery.

Hall 11, Stand A11

Rodent pests are a problem in agriculture that should not be neglected, especially because they can not only ingest stored grain and animal feed, but also contaminate it. Contaminated grain and feed can in turn cause diseases in farm animals and humans.

HyCare Digital from MS Schippers is a holistic system for rodent control on farms without the use of rodenticides. It combines natural methods of rodent deterrence, such as the colonisation of predators and habitat management, with digital monitoring and trap systems. The individual observation points and traps can be monitored via an app. The app reports corresponding observations directly to the farmer's smartphone so that he can take the necessary countermeasures. The triggering of traps is also reported so that they can be quickly checked and reactivated. At the same time, the control is also documented.

HyCare Digital thus enables targeted rodent management without unnecessarily burdening nature and the environment.

Hall 27, Stand E15

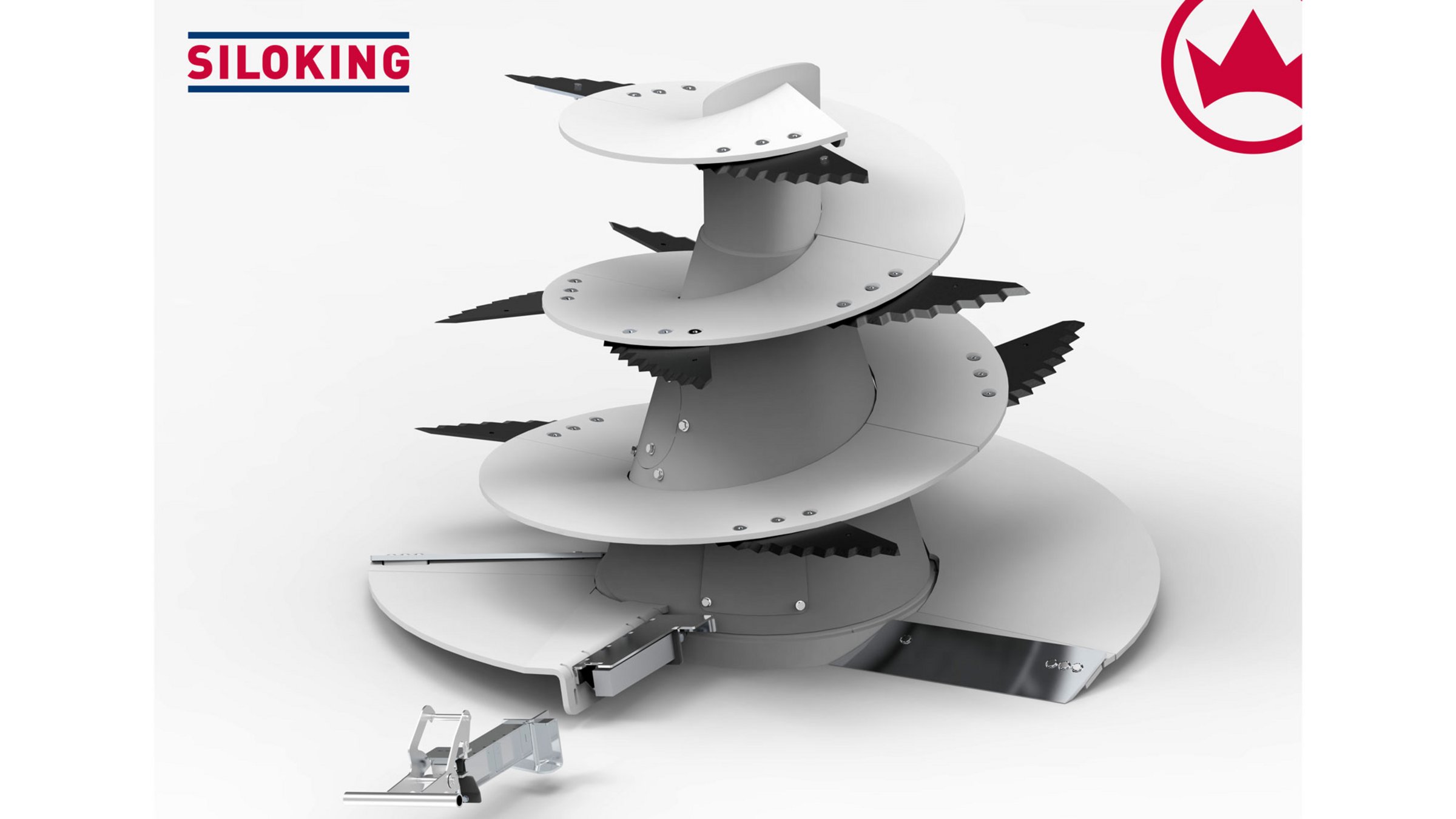

In the field of mechanised cattle feeding, foreign bodies containing iron in the mixed ration pose a considerable potential risk to the animals. The ingestion of such foreign bodies can lead to serious injuries in the digestive tract of the cattle, which can often result in illness of the animal and sometimes even the death of affected animals. To counter this problem, permanent magnets have been installed in feed mixing systems for some time, to which these magnetisable foreign bodies adhere.

Until now, however, the adhering foreign bodies had to be removed from the built-in magnet by hand. This procedure often resulted in injuries to the person carrying out the work, as knives for shredding the feed are installed in the immediate vicinity of the magnets.

With the design from Siloking Mayer Maschinenbau, the heavy-duty magnet can now be completely removed with its surrounding housing and all adhering foreign objects for the first time. This shifts the task of detaching the magnet away from the main danger zone, makes the entire task easier and significantly reduces the risk of injury.

The innovative magnet design from Siloking Mayer Maschinenbau therefore represents a significant advancement in the field of feed mixing systems.

Hall 12, Stand F23

In co-operation with

- BETEBE GmbH

- Institute of Agricultural Engineering, Christian-Albrechts-Universität zu Kiel

Animal farming is one of the focal points of national and international regulations when it comes to reducing emissions of air pollutants. Reducing ammonia emissions is particularly important here, including in cattle stables.

By developing a urease inhibitor for use on walking surfaces in cattle barns, developing a dosing, mixing and filling unit for this product and combining it with a slide valve technology with a corresponding distribution device, SKW Stickstoffwerke Piesteritz and the company BETEBE have brought a practical system to market maturity that allows ammonia emissions in cattle barns to be significantly reduced at the point of origin, i.e. in the animals' walking area. The system is considered to be functionally reliable and works largely autonomously. The combination of the application technology on the recirculating slider with a mixing and dosing technology means that daily use is easy to implement and document in terms of labour efficiency.

This makes it possible to reduce barn-specific NH3 emissions and thus undesirable nitrogen inputs into nitrogen-sensitive ecosystems, both when building new barns and when retrofitting existing barns.

The ATMOWELL technology with urease inhibitor from SKW and BETEBE is a combination of various technologies, some of which are already known, which together represent a significant improvement that promises economic benefits and makes environmental targets for NH3 emission reduction achievable.

Hall 12, Stand D03

Changing group sizes are an everyday occurrence in the cowshed. As a rule, gates are permanently installed in the barn and are difficult or impossible to change. This often results in unused space in the barn.

Spinder now offers a solution to this problem with the Spinder Track. The usable stable area can be adapted to the corresponding group size at any time using a door that runs on rails. The system is designed so that it can be operated by one person and locked in the desired position. Animals or people can pass through an integrated sliding gate at any time. The system can be installed in newly built barns as well as retrofitted in existing barns and is customised to the respective specifications of the barn. Due to the height of the track in particular, hardly any disruption to other work in the barn is to be expected.

The Spinder Track therefore enables optimum utilisation of space.

Hall 13, Stand B09

Monitoring and improving calf welfare by analysing and regulating the drinking process

Healthy, vital calves are the basis for successful milk production. Against this background, intensive observation of calves is important. Digitalisation is increasingly supporting the observation, evaluation and control of relevant processes through sensor technology and intelligent algorithms, thereby supporting animal health and well-being in calf husbandry.

Urban SipControl is an innovative system for determining the animal welfare of suckling calves at automatic feeders. The system records the animal's sucking strength and the individual swallowing processes during the feeding process in high resolution and can adapt the feeding process to the individual animal by means of active flow control. Physiologically optimised drinking times in conjunction with low swallowing volumes can therefore be implemented for each individual animal during each drinking process. Deviations from the animal-specific sucking patterns can be used for predictive health monitoring.

Urban SipControl uses a high-resolution, inductive flow sensor to scan the pulsating volume flow that occurs in the suction line of suckling calves at microsecond intervals. During the drinking process, the number of sips, the amount taken per sip and the calf's sucking strength are recorded and analysed with high precision. The length of the suckling process can be customised to the individual animal if required.

The Urban SipControl thus represents a significant further development in calf feeding on automatic feeders.

Hall 27, Stand C24

Constantly getting on and off is typical of working with a wheel loader and is not only strenuous, but also harbours a constant risk of injury. Particularly in the case of yard and wheel loaders, it is common to alternate between briefly moving the machine forward and carrying out other work.

The Follow me assistance system from Weidemann makes this work with the Hoftrac much easier. The Follow me function allows the operator to get off the vehicle and let the Hoftrac follow autonomously to the next working point. Using a handheld device, the operator can ask the Hoftrac to follow and fix it at the destination, after which it can then follow to the next point. For safety reasons, a button must be permanently pressed. A virtual safety zone is created around the machine. This ensures that the operator and the area around the machine are appropriately protected.

This system enables the user to carry out work with the Hoftrac without constantly getting on and off the machine. This also reduces the risk of accidents when getting on and off the machine.

Hall 22 Stand, C31

In order to achieve high performance in cattle farming, an optimal feed supply is essential. In particular, it is important to cover a large part of the nutrient requirement via the basic feed by optimising rumen function. On the one hand, this is the most cost-effective feeding option and, on the other, has a significant impact on animal health. The rumen environment and the rumen microbes, which ultimately break down the coarse feed, are increasingly coming into focus.

The importance of iso-acids as nutrients for rumen bacteria has long been recognised and proven. In the past, however, it has proved difficult to apply them via the feed. With the new, patented process for masking the unpleasant odour of iso-acids and further intensive research, the technical application hurdles have now been overcome and the situations in which rumen microbes can benefit from additional branched-chain fatty acids have been identified.

Zinpro IsoFerm is a mixture of volatile fatty acids. They are produced "naturally" in the rumen during the breakdown of branched-chain amino acids and are growth factors for cellulolytic rumen microbes in particular. When added in a targeted manner, they have the potential to improve microbial protein synthesis and fibre digestibility, thereby promoting rumen function, metabolism and efficiency. Trials show up to 15 % higher fibre digestion and up to 6 % higher microbial protein synthesis. In addition, new, preliminary test results indicate a potential for reducing methane production.

The addition of Zinpro IsoFerm can therefore - depending on the metabolic situation of the cow - lead to a higher milk yield in early lactation or to better persistence of the lactation curve in late lactation. This results in higher farm profitability.